品质 · 好货

品质 · 好货

质量保障/大量现货/支持定制

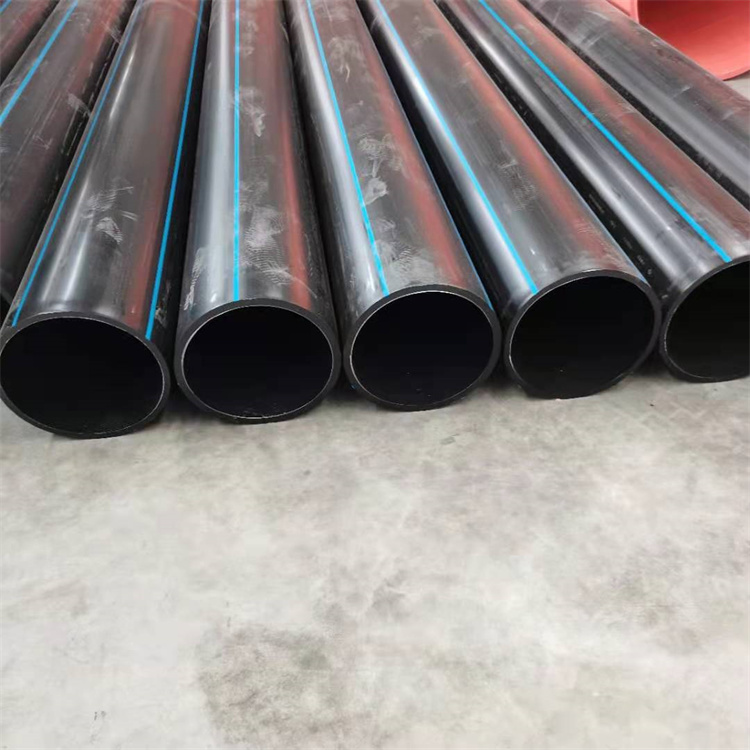

开云官方网站是一家集新材料研发、生产、销售、安装于一体的企业,生产超高分子量聚乙烯管材,钢带增强PE螺旋波纹管材,HDPE管材,钢衬塑衬胶管材,逃...

开云官方网站是一家集新材料研发、生产、销售、安装于一体的企业,生产超高分子量聚乙烯管材,钢带增强PE螺旋波纹管材,HDPE管材,钢衬塑衬胶管材,逃...

75PVC给水管连接方式 75PVC给水管的连接方式主要有以下几种: 1. **胶接**:这是PVC给水管最常用的方式,水管工用胶水连接PVC管,接口处用P...

PVC给水管的参数包括: 1. 外观:不得有气泡、裂纹、色泽不均匀等缺陷,厚度应均匀,色泽一致。 2. 耐压性能:热水管可以耐受5.5公斤的压力,冷水管可以...

UPVC给水管是聚氯乙烯管PVC管的一种,UPVC给水管采用的是聚氯乙烯全新料加工而成的,颜色分为白色或灰色,一般应用于灌溉或者居民饮用水应用中,因其价格低...

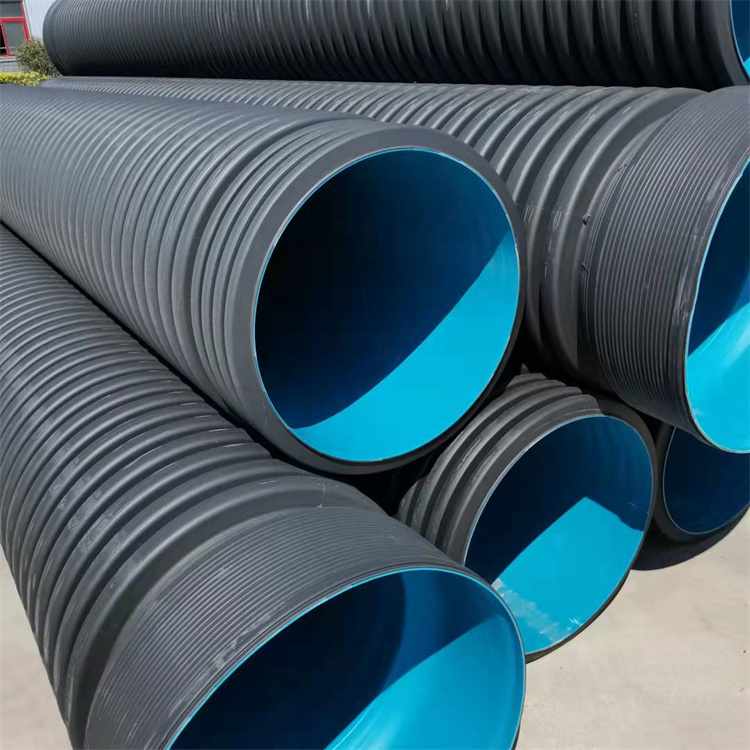

DN400口径双壁波纹管的参数包括: 1. 内径和外径:内径400mm,最小外径约460mm。 2. 壁厚:标准壁厚6mm,理论可以生产到13mm。 3....

强生产

钻研发

重品质

精服务

15194589676

工艺 · 流程

工艺 · 流程

严格把控从原材料投入到成品产出

精挑来料

下单生产

严格把控

仔细质检

完整入库

安排装车

出厂发货

聚焦 · 开云官方网站管材

聚焦 · 开云官方网站管材

开云官方网站管材带领您向“智造”迈进

走进 · 开云官方网站管材

走进 · 开云官方网站管材

开云官方网站管材用心做好每个产品

开云官方网站是一家集新材料研发、生产、销售、安装于一体的高新技术企业,专业生产超高分子量聚乙烯管材,钢带增强PE螺旋波纹管材,HDPE管材,钢衬塑衬胶管材,逃生管道,3PE防腐钢管,油井管道等管材系列产品,产品广泛应用于石油、化工、电力、矿山,冶金、医药、水利、市政、建筑,环保,炼焦,煤化,疏浚等行业领域。